News

Company News

SERVOsoft® News

- WITTENSTEIN cyber motor

publishes servo drive

solutions in SERVOsoft

Sep 29, 2025 - SERVOsoft Cloud Released!

May 23, 2025 - SERVOsoft v4.6.530 Released!

Apr 27, 2025 - Energy Storage Modules

Tutorial

Jan 12, 2025 - Winder Spooler

Hanging Load Tutorial

Aug 29, 2024 - Database Utility Import

Product Data Tutorial

Aug 28, 2024 - Master Follower with

Optimizer PRO Tutorial

Aug 27, 2024 - SERVOsoft v4.6 Released!

Aug 1, 2024 - SEW-EURODRIVE publishes

CMP and CM3C Series Motors

Feb 14, 2024 - YYC Machinery publishes

Rack & Pinion Solutions

Integrated Transmission

Components

Jan 24, 2024

SERVOsoft News

SERVOsoft® v3.3 Beta in Final Stages of Development

Apr. 13, 2014

ControlEng Corporation is pleased to announce that our most exciting SERVOsoft® version yet, v3.3, is entering its final stages of development. While it is still perhaps 2 months away from official release, we wanted to inform our users that the new version will bring big improvements in performance, features and options.

ControlEng Corporation is pleased to announce that our most exciting SERVOsoft® version yet, v3.3, is entering its final stages of development. While it is still perhaps 2 months away from official release, we wanted to inform our users that the new version will bring big improvements in performance, features and options.

We will be making a new v3.3 beta release before the end of April. And with this release, we are opening up v3.3 beta testing to all SERVOsoft Power Users with PRO licenses. Please contact SERVOsoft Support if you are interested in beta testing v3.3. We will add you to the email list to be notified when the next v3.3 beta is available.

Here are the details...

Performance

- Database Product Selection

- First and foremost, we have improved the loading of the product database performance by 2-5x compared to v3.2, really speeding things up. And for those situations where a query is taking a long time, we have added the "Abort" button to kill the process, so you can make changes to your filters and optimize your product search quickly without having to wait for a query to finish.

- Database Utility

- The Database Utility performance has also improved by over 10x compared to v3.2. Now the entire database can be imported into a blank database in less than 5 minutes. Yes, 5 minutes. In v3.2, this took hours.

- Sequence Templates:

- The Sequence Templates froms now load 4x faster than in v3.2.

- Charts:

- Export Data feature optimized with up to 10x performance improvement (wrt v3.2).

- Generally throughout the program, tasks are 25% faster.

New Options

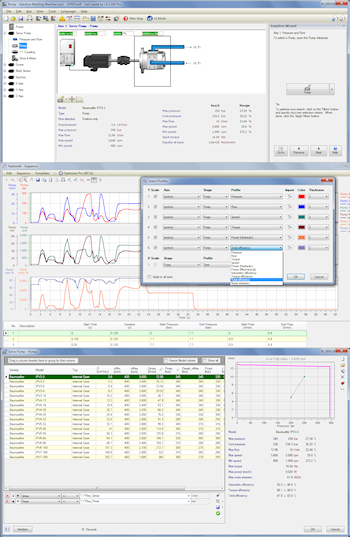

- Servo Pump (beta)

- Working in close partnership with Baumueller, we have built the Servo Pump option, which allows users to size and select Servo Pumps, as well as Motor-Coupling-Pump combined products.

- Unidirectional and Bi-directional flow pumps are supported.

- A dynamic pressure and flow vs time sequence is supported, which allows users to create any pressure and flow vs time sequence that is required. As shown in the Pump Sequence screenshot above, this is a fully dynamic model.

- In the Sequence form, users can display pump pressure, flow, torque, speed, power (hydraulic), power (mechanical), volumetric efficiency, torque efficiency, total efficiency and noise emission.

- Optimizer Pro (beta)

- The Optimizer Pro has been almost entirely re-written to handle a much broader range of optimization limits and constraints.

- For example, it takes what is an impossible manual task, and reduces it to a few clicks to optimize the Slider Crank mechanism motion profile for minimal torque. Set your parameters and constraints, click 'Start', and let the Optimizer Pro do the work!

- Note that in v3.3, this feature will be released as a beta since we want to give it some more field testing, and do not want to hold up the release of v3.3.

Enhancements

- Drives and Infeed Modules with Switching Power Supplies:

- Added support for Drives and Infeed Modules with switching power supplies, which provide a controlled DC bus, but do not regen power back to the mains supply. This is handled in the v3.3 database by setting the 'Supply to Bus Factor', SBus = 0. In this case, regardless of the mains supply voltage, the automatic values for the nominal and threshold bus voltages will be Vo and Vmax.

- Rotary Motor Model:

- Added Torque vs Current Exponent, ktExp, database field, which allows for specifying the exponent value in the torque vs current motor model. This allows even more accuracy for those vendors who want to use it. When not specified, ktExp is handled the same as in v3.2, where ktExp = 2 or best fit when 2 is not a suitable value.

- Linear Motor Model:

- Added Torque vs Current Exponent, kiFExp, database field, which allows for specifying the exponent value in the torque vs current motor model, allowing for even more accuracy for those vendors who want to use it. When not specified, kiFExp is handled the same as in v3.2, where kiFExp= 2 or best fit when 2 is not a suitable value.

- Gear Motors is now a 'Combined Product' of 'Motor + Gearbox', making it so much easier for vendors to handle their gear motor products in the SERVOsoft database. Also minimizes duplication of product data.

- All Databases:

- When the Vendors filter list is loaded, now only vendors are included in the list if one or more of their products exist in the specific database table

- Rotary Mechanism:

- Added Load Mass, Disc Mass and Disc Friction Coefficient

- Conveyor Mechanism:

- Added 'Belt -> Slide Friction Coefficient' input

- Energy Cost Analysis:

- Added option in the 'Details' tab 'Years' list to select energy costs per 'cycle'

- Motor & Drive database:

- When the user opens the Drive & Motor database with no products selected, then selects a motor and clicks 'OK', in v3.2, the first drive listed was also selected automatically even if the user had not selected the 'Drive' tab to view the drives list. In this case, perhaps the user was only interested in the motor. So to avoid this problem, now a drive is not selected unless the user first clicks on the 'Drive' tab to view the drives list. Ie. if the user never looks at the drives list, then no drive is selected. And in the case where there is an existing selected drive, this selection is not changed.

- Extensive additions and improvements to the Help file